Inductive elements in power electronics systems operate under the presence of higher harmonic currents and currents with frequencies generated by switching of semiconductors. Example of applications include inductance of passive and active filters and motor chokes, operating at the output of frequency inverters [1,2]. Difficult operating conditions cause a number of technical prob-lems. Inductive chokes are often a source of noise, electromagnetic interference and excessive power losses. The article presents the properties of chokes with multi-gap cores made in the innovative ElhandCutCore TM technology, intended for use in power electronics applications.

Choke's leakage flux

A complex design issue is a correct determination of choke's power losses. The reason for difficulties is presence of a leakage flux in the air gaps around the core. This flux results in additional power losses in the core, structural elements of the core and even in winding of the choke. In the extreme cases, leakage of the choke may be so large that leakage flux will be engaging with ferromagnetic elements located near the choke (e.g. casing) causing power losses in them. Losses cre-ated in this case can be formed as eddy-current and hysteresis [3]. The classic technological solution to restrict losses in the core is the application of magnetic material with a very narrow hysteresis loop, which provides low hysteresis loss and assembly of the core from insulated metal sheets with thickness as low as possible in the direction of the flux. This technology is very effective in transformer cores. In the case of cores of chokes where we are dealing with discontinuity of the core at places of air gaps, assembly and good magnetic material alone are no longer sufficient. In the areas near gaps there is a change in the direction of the flux, and hence very intensive generation of eddycurrent losses in the core material, winding and in conductive elements within the flux range [4, 5].

Linearity of choke's magnetic characteristics is an important utility parameter. The achievement of the required linearity forces the application of extensive use of air gaps in the core, which leads to increased power losses and temperature rise, especially in the areas near the gaps. The presence of substantial differences in temperature between particular areas of the core, winding or structure of the choke is a direct consequence of additional power losses. In the case of classic chokes' core design, it is not easy to determine the values of losses and temperature by using analytical methods. It is difficult to calculate additional power losses related to excessive leakage flux around gaps, the source of which are currents with harmonic frequencies and PWM. These additional power losses may exceed basic losses in the core and winding of the choke.

Magnetic and magnetostrictive forces operate on the periodically remagnetized magnetic core. Forces generate variable stresses in sheets of the core and cause vibrations of structure elements, resulting in acoustic field around the choke [6]. The size of magnetic and magnetostrictive forces depends on maximum, local values of magnetic induction, in particular in areas with disturbances in the direction of the flux in the core. Locally in the core there may occure a significant increase in induction. Periodical saturation of magnetic core fragments and related formation of local centers of losses and vibrations are difficult to control without a thorough analysis of the thermal model of the choke and radical changes in the core production technology.

Core in the ElhandCutCoreTM technology

As a result of development and research carried out at ELHAND Transformatory Sp. z o.o., an innovative technology for production of multigap core was established: ElhandCutCoreTM. Longterm production experience and analysis of the magnetic field distribution in the core, made it possible to create a choke cores’ production technology which significantly restricts or completely eliminates all of the technical problems.

|

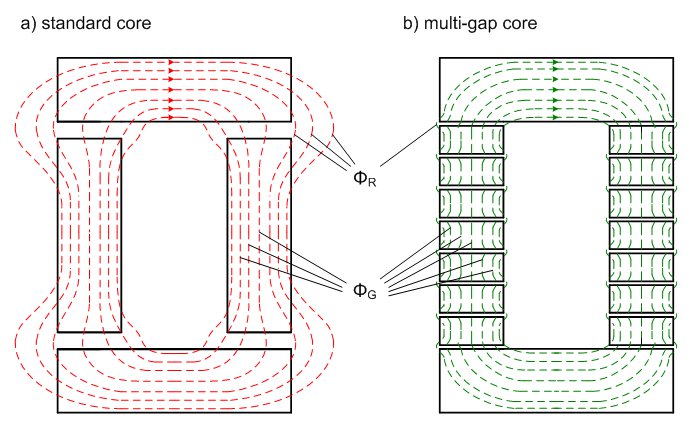

| Fig. 1 Run of flux in: a) standard core, b) multi-gap core ΦG-main flux, ΦR-leakage flux |

The core made in the ElhandCutCoreTM technology allows for a constant inductance value in a wide range of changes in the choke's current (magnetic linearity), reduces the noise generated by the choke and eliminates external magnetic field. This allows for additional losses in the core, winding and structural elements to be reduced. Arrangement of corresponding sequence in the core air gap, in combination with a precise determination of their width, enables to shape the distribution of electromagnetic field inside and outside the core (Fig. 1). A division of an air gap reduces the adverse impact of the leakage flux and allows for even distribution of induction in the choke's core.

ELHAND Transformatory Sp. z o. o. produces high quality, low-loss chokes with multi-gap cores in the ElhandCutCoreTM technology, applied, among others, in power electronics, mining industry, rail transport, as well as wind power industry.

Literature

- Łukiewski M., Dławiki silnikowe, Wiadomości Elektrotechniczne, 3 (2001)

- Morozow I., Łukiewski M., Dławiki współpra-cujące z energooszczędnymi przemiennikami częstotliwości., Napędy i Sterowanie, 5-6 (2005)

- Dąbrowski M., Analiza obwodów magnetycz-nych. Straty mocy w obwodach. PWN, Po-znań(1981)

- Roshen W. A. Fringing Field Formulas and Winding Loss Due to an Air Gap, IEEE Trans. on Magn., vol.43, no.8 (2007)

- Bossche A., Cekov Valchev V., Improved cal-culation of winding losses in gapped inductors, Jurnal of Applied Physics 97, 10Q703 (2005)

- Łukiewski M., Hałas dławików indukcyjnych, Napędy i Sterowanie, 12 (2008)

At the beginning of year 2015 we put into operation the "TESTING STATION FOR MEDIUM VOLTAGE TRANSFORMERS”. The main components of the station were designed and delivered by famous companies HAEFELY HIPOTRONICS (CH) i TELAB (PL).

This equipment enables us to perform following tests and measurements:

- insulation strength with testing voltage,

- insulation strength with induced voltage,

- measurement of winding resistance,

- measurement of insulation resistance,

- measurement of voltage ratio and check of phase displacement,

- measurement of no-load loss and no-load current,

- measurement of short-circuit impedance and load loss,

- measurement of partial discharges level with the registration sensitivity below 1 pC,

- temperature rise test

- measurement of emitted noise level with suppression of background level 40 dB and with the

reverb decay time of 0,15 s.

|

|