| Symbol and designation | Standard | Description |

| V | EN 61558-1 | Volt |

| A | EN 61558-1 | Ampere |

| VA | EN 61558-1 | Volt-ampere |

| W | EN 61558-1 | Watt |

| Hz | EN 61558-1 | Hertz |

| PRI | EN 61558-1 | Input winding (primary winding) |

| SEC | EN 61558-1 | Output winding (secondary winding) |

|

EN 61558-1 | direct current |

| N | EN 61558-1 | neutral terminal |

|

EN 61558-1 | single-phase alternating current |

|

EN 61558-1 | Three-phase alternating current |

|

EN 61558-1 | Three-phase alternating current with neutral wire |

|

EN 61558-1 | class II construction |

|

EN 61558-1 | class III construction |

|

EN 61558-1 | fuse |

|

EN 61558-1 | slow blow fuse |

|

EN 61558-1 | enclosure terminal or core terminal |

|

EN 61558-1 | earthing terminal |

|

EN 61558-2-2 | fail-safe control transformer |

|

EN 61558-2-2 | non-short-circuit proof control transformer |

|

EN 61558-2-2 | short-circuit proof control transformer (inherently or non-inherently) |

|

EN 61558-2-1 | fail-safe separating transformer |

|

EN 61558-2-1 | non-short-circuit proof separating transformer |

|

EN 61558-2-1 | short-circuit-proof separating transformer (inherently or non-inherently) |

|

EN 61558-2-4 | fail-safe isolating transformer |

|

EN 61558-2-4 | non-short-circuit proof isolating transformer |

|

EN 61558-2-4 | short-circuit proof isolating transformer (inherently or non-inherently) |

|

EN 61558-2-6 | safety isolating transformer |

|

EN 61558-2-6 | fail-safe safety isolating transformer |

|

EN 61558-2-6 | non-short-circuit proof safety isolating transformer |

|

EN 61558-2-6 | short-circuit proof safety isolating transformer (inherently or non-inherently) |

|

EN 61558-2-19 | non-short-circuit proof isolating transformer attenuating disturbances |

|

EN 61558-2-19 | short-circuit proof safety isolating transformer attenuating disturbances |

|

EN 61558-2-13 | fail-safe safety autotransformer |

|

EN 61558-2-13 | non-short-circuit proof autotransformer |

|

EN 61558-2-13 | short-circuit proof autotransformer (inherently or non-inherently) |

|

EN 61558-2-20 | choke without overload protection |

|

EN 61558-2-20 | choke with overload protection |

|

EN 61558-2-15 | non-short-circuit proof isolating transformer for supply of medical location |

Electrical equipment is required to meet the relevant international and national standards.

A standard is a document which describes suitable electrical and mechanical design, construction and test requirements to provide for safe and reliable operation within a specific working environment.

Dry-type transformers: The following standards apply:

- International – IEC60726 ; IEC60076 ; IEC61558

- European – EN60726 ; EN60076 ; EN61558

- Other e.g. – GOST (Russian)

Chokes: The following standards apply:

- International – IEC60726 ; IEC60076 ; IEC61558

- European – EN60289 ; EN60938 ; EN61558

- Other e.g. – GOST (Russian)

Depending on intended use, an equipment should also meet the requirements defined by certain classification societies and is required to be certified accordingly. Conformity and certification by such societies should be indicated on the equipment.

Shipyard industry: Supervision and certification is required by the following classification societies:

- ABS – American Bureau of Shipping - USA

- BV – Bureau Veritas - France

- CCS – China Classification Society - China

- DNV – Det Norske Veritas - Norway

- GL – Germanischer Lloyd - Germany

- LR – Lloyds Register of Shipping - Great Britain

- NKK – Nippon Kaiji Kyokai - Japan

- RINA – Registro Italiano Navale - Italy

- PRS – Polski Rejestr Statków - Poland

- RMRS – Russian Maritime Register of Shipping - Russia

Armed forces: Equipment is required to meet National Military Institution for Quality Assurance Affairs and have:

- AQAP certificate – Issued by National Military Institution of a country belonging to NATO. ELHAND company own such a certificate, AQAP no. 2120:2006 and 644/A/2008

- NCAGE code – NATO Commercial and Governmental Entity Code issued by Military Center for Standardization and Codification – Codification Branch for Defence Products.Code no. 1394/H/2007 was granted to the Elhand company.

Mining: Equipment should be certified to the relevant mining application and issued by the appropriate testing laboratory or certification body of a given country.

CE mark: The CE mark was introduced as a directive of the European parliament. The CE mark, placed on the product, guarantees that it was manufactured and tested in accordance with the relevant regulations. The CE mark is primarily concerned with the “safety and health of equipment users and the influence of the equipment on the environment”.

The CE mark indicates that the product is safe and can be sold within European Union markets. The responsibility for correct use of the CE mark rests with the manufacturers, distributors and agents of an equipment. The CE mark is not a proof of product quality. The following European directives apply:

Machinery Directive (MD) no. 2006/42/WE - This Directive regards complete machine parts.

Electromagnetic Compatibility Directive (EMC) no. 2004/108/WE - This directive is relevant to devices which produce, or are susceptible to, electromagnetic interference. It does not regard the equipment which may produce interference in the transient states.

Low Voltage Directive (LVD) no. 2006/95/WE - This Directive describes the requirements for electric equipment operating in the following voltage ranges:

- Alternating voltage from 50Vac to 1000Vac

- Direct voltage from 75Vdc to 1500Vdc

COMMISSION REGULATION (EU) No. 548/2014 of 21 May 2014 on implementing

Directive 2009/125/EC of the European Parliament and of the Council with

regard to small, medium and large power transformers.

Product manufactured in accordance with the requirements of above-mentioned Directives should:

- be marked with the conformity mark

- have the declaration of conformity

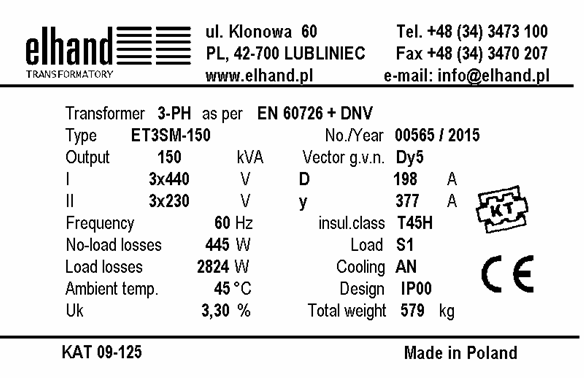

We conduct 100% test and measurement during and at the end of the manufacturing process. The scope of this testing is determined by the standard to which the product was designed and manufactured. Results of measurements are included in a test protocol and on the product rating plate. The transformer rating plate should include basic data relating to the transformer and the manufacturer. Included are:

- Identity and address of manufacturer

- Standard to which the transformer is produced

- Type of transformer

- Factory no. and year of manufacture

- Rated power

- Rated voltage and current

- Vector group

- Rated frequency

- Insulation class and ambient temperature

- Type of operation (where not included, continuous operation - S1 is assumed)

- Cooling method

- Protection degree

- Short-circuit voltage

- Total weight

- Auditor symbol and certificate number issued by classification society providing acceptance.

Additional product information can be placed on the rating (name) plate at customer’s request.

Example of rating plate (DNV approval and regulations):